Some examples of the type of issues identified while at customer locations:

Many times the issues on a vision system can be obvious, when you understand the root cause from poor information appearing on the inspection report.

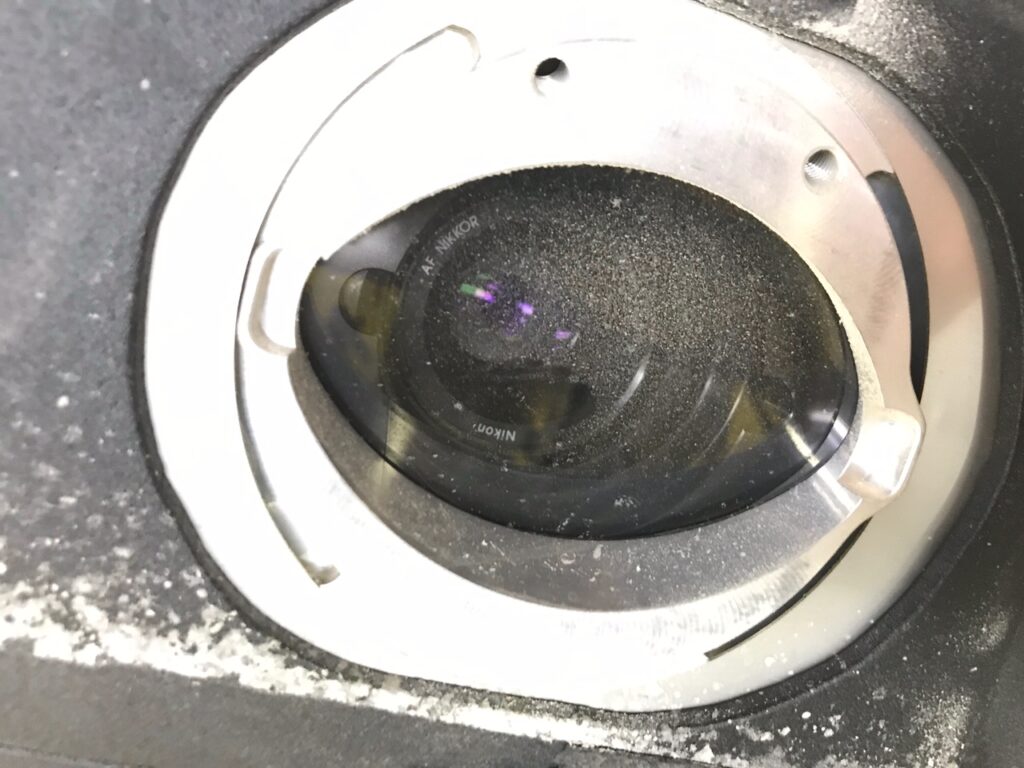

For example inside the camera lens:

Above image, a rarely checked area is to look on the inside of the camera lens. If the air that is cooling the cameras in the beam has impurities or has a high moisture level, it’s not uncommon for these impurities to collect on the inside of the camera lens.

Addressing areas like impurity collecting on the inside of cameras can dramatically improve the camera signal

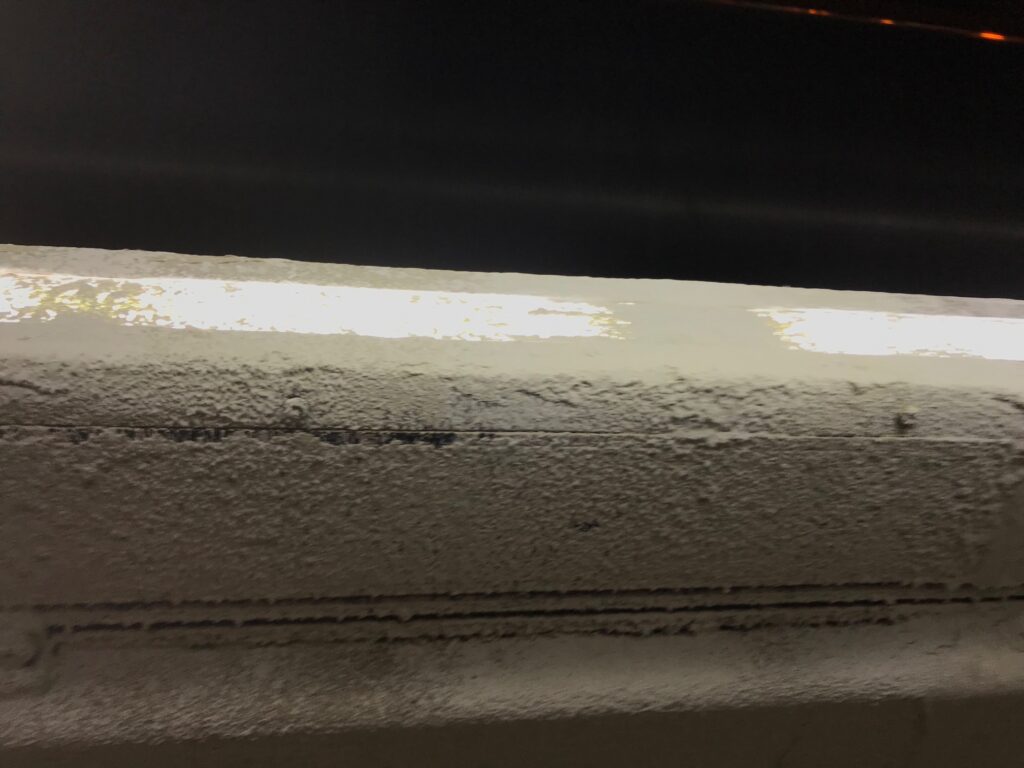

Another example is when dirt collects on the outside of a camera lens:

Image above is an example of dirt building up on the outside of a camera lens. Over time this will also dramatically reduce the signal that the camera is able to see. This will eventually make it almost impossible to see defects in the sheet

The third camera lens issue is dirt on the actual camera lens itself:

The image above shows how coating flakes area able to collect on a camera lens over time.

The final example is extreme, but it can happen and it is worth checking to see if any camera is impacted by this issue. This is especially of concern when cameras are below sheet, in a dirty environment:

Above image is a real-world example of finding a chip sitting on the camera sensor. This was causing a continuous defect to appear on the inspection report. It also caused massive file size, which in turn shut inspection off, due to the hard drive not being able to inspect.

Signal issues can come from LEDs too. An LED can have bad segments and an LED can have buildup.

The next example is a great example of when coating material is allowed to build up on an LED:

Image above shows what happens when an LED on a coating process is neglected for several weeks.

This LED with coating buildup is a perfect example of the need for scheduled maintenance as frequently as daily when a vision system is in a harsh environment.

Other factors that will impact vision systems come from the environment that the camera are asked to operate in for 24 hours a day, 7 days a week.

The connectors in the above image were still functional, however there is no question that the quality of the connection was shortly going to create issues and the camera would start to fail.

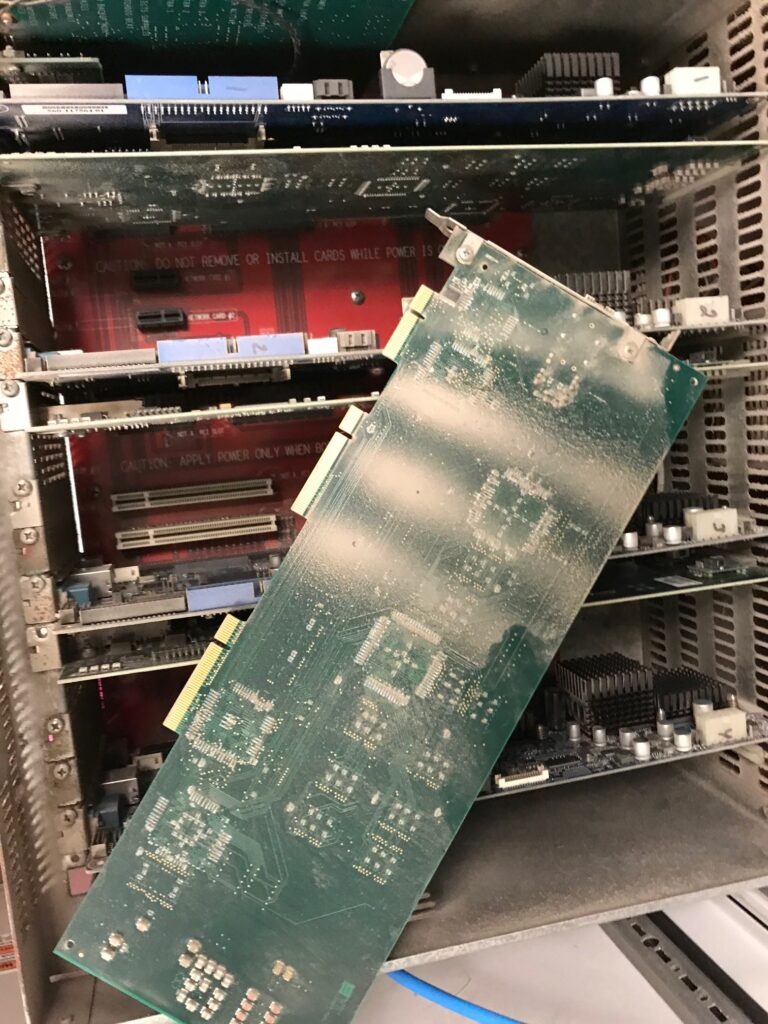

The environment can also have a negative impact on printed circuit boards. These boards should be checked frequently to see where attention may be required. Buildup like this will also indicate where filtration issues exist in air handling. These filtration issues should be addressed immediately. The cost of repairing filtration is minuscule compared to the impact of losing inspection for hours or even days, while parts area being shipped to side